(Procedure for Best: Quality, Speed, & Profits)

By Christopher Brown of OCDCarCare.com

Best Detailing Paint Correction Method as a title or phrase sounds too good to be true. Or is it?

This is not a YouTube or TikTok ‘quick fix,’ ‘hot tip,’ or a means to instant results– its a Method.

A Methodology is an approach that requires knowledge, understanding, and practical proficiency in regards to technical hands-on skills.

Proficiency requires thousands of mental and physical repetitions. Repetitions of proper execution are what embed themselves into technique, transforming that technique into stronger and stronger brain synapses. The pinnacle of technique is intuitive execution.

All of this is to say – if you want a 2min means of instant mastery, look elsewhere. It doesn’t exist. Whoever is selling that to you was most likely themselves sold on that “sales or marketing technique” by an ‘internet marketing guru.’

Have fun with that to actually help your auto detailing business!

If you want info that will illuminate a starting path to improve your detailing paint correction, then you’re in the right place.

If an Approach Provided The Best Detailing Paint Correction Method, Including:

- Increasing The Overall QUALITY of Your Paint Correction…

- Allowing Your Processes to be FASTER and MORE EFFICIENT…

- Greatly Raising Your HOURLY PROFIT MARGINS…

Would It Interest You?

Great, Because ‘Non Diminishing’ Abrasives Accomplish ALL Three!

. . . Read on to Learn How!

How on Earth can Paint Polishing Abrasives be Worth Discussing?

Paint Correction, within Auto Detailing, is often a marquee or foundational process for many detailing packages; including ceramic nano coating applications. These popular services have radically changed the business models of many detailing businesses, making them substantially more popular and profitable.

For this reason, it is important to discuss product technologies which enhance essential services within auto detailing businesses.

This Article will explore the function of ‘Non Diminishing’ Abrasives and explain why the technology leads the best detailing paint correction method for High Quality Results, Ultra Efficiency & Maximum Profits.

This discussion centers around utilizing ‘Non Diminishing’ Abrasives containing a low amount of solvents. “Chemical Cut” – meaning chemical agents used to intentionally open paint pores, in order to reach defects, is another deeper conversation for another time.

Therefore, in the context of this article, it is preferable to use a low solvent correction liquid. This reduces automotive paint swelling during polishing, avoiding a number of issues such as: paint integrity, hiding defects, ‘phantom water spots‘, and interfering with ceramic nano coating applications.

Advantages of ‘Non Diminishing’ Abrasives Explained

While there are many correction liquids on the market, there is one technology type that is head and shoulders above the rest…

That is, IF the priority is to achieve the best detailing paint correction method, featuring:

- The highest quality finish

- The most efficient and quickest results

- While being safest for vehicle surfaces

.. then ‘Non Diminishing’ Abrasive correction liquids are the clear choice.

The reasons for this are many:

Non-Stop + Consistent Cut

Correction liquid abrasives are clustered into ‘balls’ called agglomerates. These clusters help to give each correction liquid its level of cut. Since these agglomerates form a single structure they have long been referred to as ‘abrasives’ in the detailing industry.

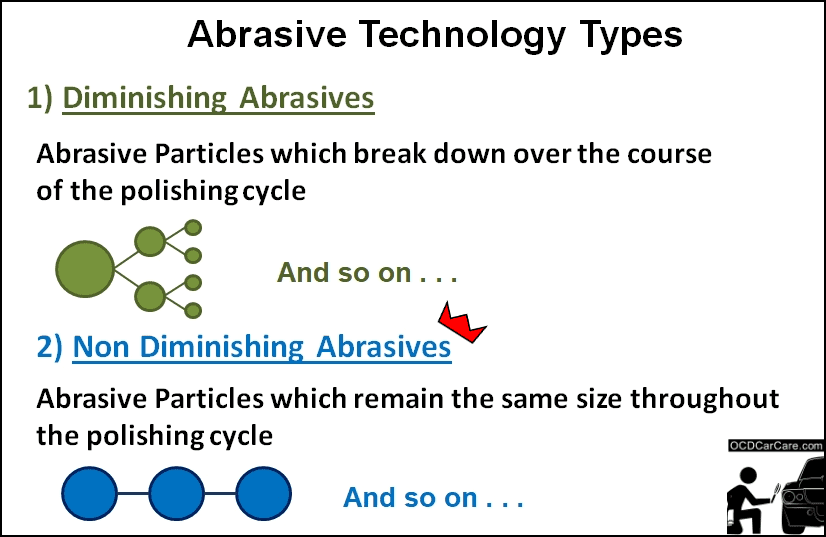

‘Non Diminishing’ Abrasives (NDA’s) agglomerate clusters do not break down (diminish) over time. As a result, they always provide a constant and consistent cut during a polishing cycle.

This makes NDA’s simple to use because they are straightforward. There are no additional variables of “when” and “how much” the abrasives will break down during a polishing cycle.. This consistent cut allows for a quicker reading and understanding of the paint system due to an accurate rate of material removal from the surface.

Furthermore, there is no chance that one, or a few, of the original large sized particles will become lodged in the pad and then randomly release at a later time. This is a problem during a finishing cycle since the larger more aggressive abrasive particle would scour the surface.

Analogous Scenarios: Picture Needing to Sand a 10ft – 50yr old solid oak rustic door before repainting…

For quality, workflow, and labor considerations, which scenario is best:

- A sheet of sand paper to change its cutting ability after 10-25% of the door is completed? With that same sheet of paper potentially diminishing its full cut capability to a point of being near useless, with about 50-60% of the door left to sand?

- The sand paper retains the same cutting capability throughout the process?

The second, right? Because, a consistent abrasive allows for complete control of the consistency of quality, efficiency, and accurately booking and executing labor time.

Wouldn’t it be annoying to constantly go back over areas and HAVE to redo them because the decaying grit of the sandpaper lessened results?

Does it seem logical to say, this scenario would not produce much efficient work- BUT WOULD cause consistent frustration?

This is because the abrasives embedded in the sandpaper were constantly breaking down to a less aggressive state.

Most would agree this technology of sand paper doesn’t sound ideal for sanding a simple door.

So WHY would anyone want to use Non-Diminishing Automotive Abrasives for automotive paint correction, adding Additional Variables, Inconsistent Results, and Additional Labor and Materials to the process?

Of course this all hangs on the premise that the primary objective of paint correction is to make maximum improvement while minimizing the amount of material (paint) that is removed from automotive surfaces!

Less Heat Generated during the Overall Paint Correction Process

Since ‘Non Diminishing’ Abrasives continually work to remove material (paint) they don’t require long or extended polishing cycles to cut. This means less passes with a machine, pad, and abrasive reduces the overall amount of friction over a panel. Lower levels of friction on a panel help reduce heat related issues for panels such as: the hiding of defects (caused by paint swelling) or even possible paint burning.

Greater Labor Efficiency

Since paint correction with non-diminishing abrasives is a more efficient process, the time for quality results is greatly reduced. This can directly lead to an increased hourly rate or more jobs completed over a day, week, or months’ time.

Less Stress/Wear on Operator, Tools, Pads

A more efficient process of paint correction, using NDA’s, leads to less stress and wear on detailers, machines, and pads. This leads to increased profitability for employee labor. Additionally, less stress on a detailer’s body leads to better results and a happier demeanor when working.

Less stress on machines and pads enables more mileage on these costly tools and more jobs completed by both. This combination helps greatly to keep ‘material costs’ down per job.

Paint Residue Builds up Quickly with ‘Non Diminishing’ Liquids: So Clean Pads Frequently!

When using NDA’s paint residue builds up QUICKLY on pads. Hard paint material is removed quickly, since the liquid always cuts at max rate. This means pads quickly load with paint residue and used product.

At a certain point, the level of residue will build up and start to clog the pad. The more residue built up in a pad, the slower the cutting process. Additionally, if allowed, over saturation of built up reside on the pad surface will start to scour or haze the finish.

For this reason, pad cleaning is CRITICAL when paint polishing with ‘Non Diminishing’ Abrasives. Compressed air is, by far, the best means of removing residue from pads. Therefore, blow out pads after completing each working section.

While air is very effective at removing residue from pads, it does not remove everything. Therefore, plan on using a bare minimum of four to six (4-6) pads per vehicle, to stay ahead of pad residue build up. More may be necessary due to total vehicle size and overall paint dynamics.

This guideline is per stage or phase of correction. So if a two phase paint correction is required (compounding and polishing) then 4-6 pads are needed for the compounding and 4-6 additional pads are needed for the polishing phase.

Four (4) to six (6) pads per vehicle is a solid starting point. Also, depending on the workflow and time constraints for a job, it may be necessary, faster, or perform better to switch out pads more frequently and clean them later.

“LONG WORKING TIME” is Unnecessary Marketing Hype for Compounds & Polishes

“Long working time” is one of the most over used marketing terms (and misunderstood concepts) in the auto detailing industry in regards to compounds and polishes.

Companies want consumers to believe that “long working time” is an advantage. The term implies more work occurs during a longer polishing cycle. However, at the pad surface level, this is not the case at all.

Diminishing abrasive based liquids cut to a certain point and stop because they break down. Let’s call this point “X”.

After X, not much correction occurs because the abrasive is: broken down, smaller, and less aggressive.

Therefore, the abrasive’s cutting capability is greatly diminished or gone compared to its fresh starting point. At point X, or beyond, the diminishing compound or polish smears around hard paint residue, collected by the pad, and scours the surface. This is the opposite of cutting.

In contrast, ‘Non Diminishing’ Abrasive based liquids do not stop cutting during a polishing cycle.

This means the pad will eventually reach a tipping point and it will become oversaturated and full of paint residue. These elevated levels of paint residue build up, reducing the capability of the pad to cut and to accept residue. High levels of paint residue within a pad drastically reduce the overall cutting capability.

For this reason it is important to frequently clean pads when using NDA’s, as discussed previously in the Paint Residue section.

However, consistent marketing speak somehow made the term ‘long working time’ standard language and a sought after characteristic within the industry.

Most detailers often blindly over cycle all correction liquids for long periods of time. It seems these individuals are looking for some sort of ‘visual indicator’ for when to stop polishing.

Often times what they observe is the emulsion within the liquid breaking down or the abrasives attaching themselves to large paint particles and embedding themselves within the pad. In short, a perceived ‘visual indicator’ of a compound or polish on a panel does not accurately indicate a polishing cycle’s end.

‘Long Working Time’ Correction Liquids Typically Contain Heavy Carrier Oils

Diminishing Abrasive liquids, featuring ‘long working’ times, often contain medium to heavy carrier oils.

These oils keep the liquid ‘workable.’ However, these medium to heavy carrier oils presents a few issues to detailers:

- Heavier carrier oils stubbornly cling to clear coat in an aggressive fashion or they smear, creating removal issues. (Think bacon grease clean-up on marble)

Adding extra time or steps for compound or polish removal can slow down the paint correction process. Also, excess friction can wreak havoc on finicky paint, causing potential marring or worse. This occurs when additional pressure or additional wiping steps are needed for removal. - Heavier carrier oils are robust and difficult to remove for most panel prep or IPA (isopropyl alcohol) solutions.

This can cause potential bonding issues for long term ceramic nano coating applications. This is a problem since carrier oils create a barrier between the clear coat and the coating. This interferes with optimal bonding of the coating and the clear coat. - Heavier carrier oils tend to ‘fill’ the paint, hiding the actual condition of the surface.

Often a finish may look great after wiping off a super easy to use final polishes claiming ‘superior’ results. However, if the same panel is followed by a panel prep, capable of removing heavier carrier oils, the finish is less appealing. The heavier oils, used to make the product easy to use and wipe off, may fill the surface and have the potential to hide defects during paint correction. - ‘Long Working’ compounds or polishes tend to have a much greater quantity of carrier oils within the liquid composition, further complicating the removal process.

‘Non Diminishing’ Abrasives Pair Perfectly with Short Polishing Cycles

Because NDA particles do not lose their cut over the course of a polishing cycle (the time the product is used on a panel), there is no need to work them for ‘long periods of time.’

In fact, by doing this is counterproductive to the paint correction process. This point is magnified when NDA’s are paired with microfiber pads and primed with product to coat each individual MF pile (strand). In this scenario, cutting occurs at an extremely fast rate. For this reason, a short polishing cycle is preferred to maximize cut and to minimize pad residue build up.

How to Polish with ‘Non Diminishing’ Abrasive Liquids – Hint: It’s Different!

‘Non Diminishing’ compounds and polishes are engineered to work fast and efficiently. They cut constantly and consistently and are best when used with short polishing cycles and frequent pad cleaning. Therefore, to optimize NDA correction capabilities on every paint system, a controlled test spot is essential to the process. With this methodology, a detailer can evaluate if: the combination of paint defects, severity of defects, the rate of material removal, liquid, pad, and machine choice all work effectively toward the desired result.

After determining the proper combination of machine, pad, and liquid detailers can calculate how many passes are generally required to refine the finish. This serves as a process baseline, or general guideline, for the entire vehicle. There is zero efficiency in blindly ‘long working’ a liquid to 8-12 passes when the job could have been done in 3-4.

Why ‘Non-Diminishing Abrasive’ Liquids are best overall for Paint Correction:

In short ‘Non Diminishing’ Abrasives are King of Paint Correction Liquids due to:

- Greater Efficiency (quickly removing defects & consistency during polishing cycle)

- A Higher Quality of Polishing (due to reducing the # of active variables during polishing)

- Labor time savings + prolonged pads and machine use = Greater Profitability

- Heat Reduction during Polishing Eliminates or Reduces Many Paint Related Issues

- Safer for Painted Surfaces due to less time polishing & ease of removal

Final Thoughts on ‘NDA’s’ inside The Best Detailing Paint Correction Method

If the Goal of Paint Correction is:

- To obtain the best results

- In the least amount of time

- While being safest on the paint

then pairing ‘Non Diminishing’ Abrasives with Short Buffing Cycles is the best detailing paint correction method.

With this methodology, both greater profitability and higher quality results will occur while lessening user fatigue and total time to complete jobs.

These results and profitability are the ‘holy grail’ of polishing which detailers are constantly looking for. It exists, however it does not simply occur with products alone, as many chemical manufacturing companies may claim.

Instead, this ‘holy grail’ of polishing requires mentally understanding the relationship between: correction liquid type, pad choice, machine choice, paint dynamics, procedures, and client preferences for the job at hand. This takes knowledge, time, training, and a constant discipline to achieve, requiring effort and practice.

“ALWAYS Keep Learning to Strengthen Your Passion & Your Business.”

© Christopher Brown – OCDCarCare Los Angeles

Want to Elevate Your Detailing Business to the Next Level?

INCREASE Your: Knowledge, Quality, Confidence, Efficiency, & Profits…

For more auto detailing articles & car care related topics check: OCDCarCare Los Angeles’s – Auto Detailing Article Archive

- Vehicle Water Spots Explained: Formation, Removal, & Prevention - 28 August, 2023

- Automotive Paint Thickness Gauge (PTG): Detailing User Guide - 2 September, 2022

- 5 Thin Automotive Paint Layers Explained For Detailing - 10 July, 2022